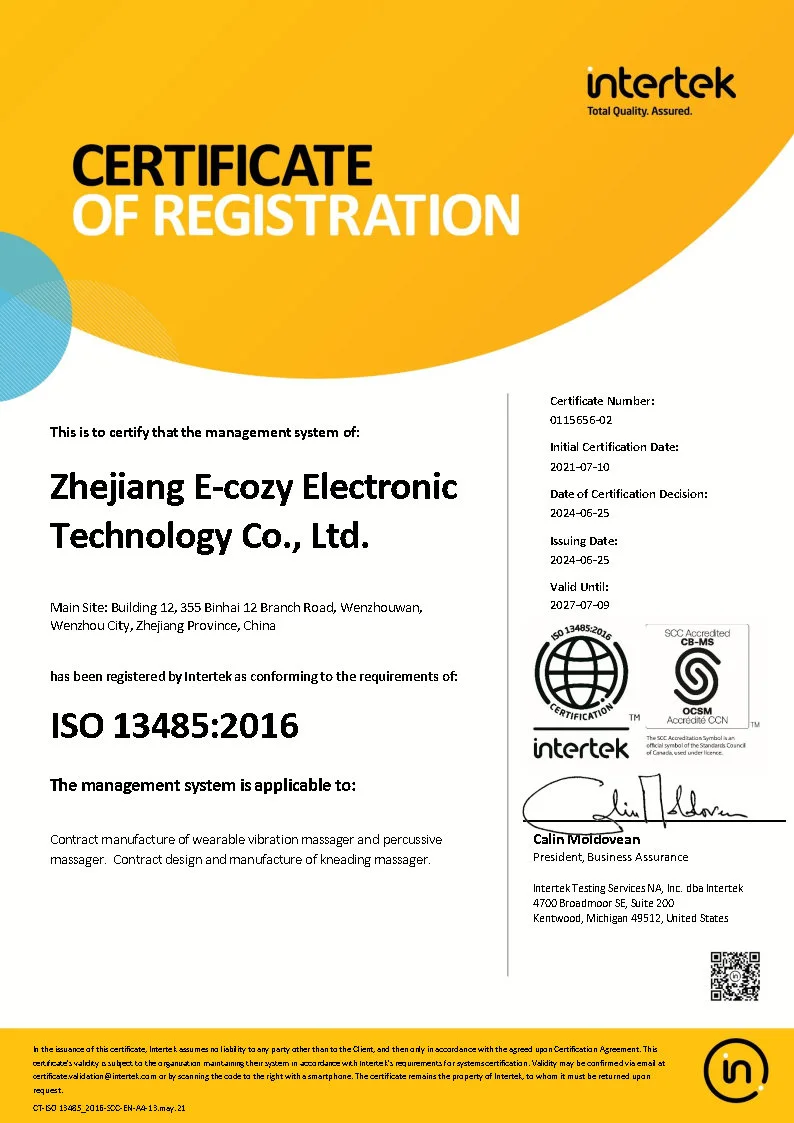

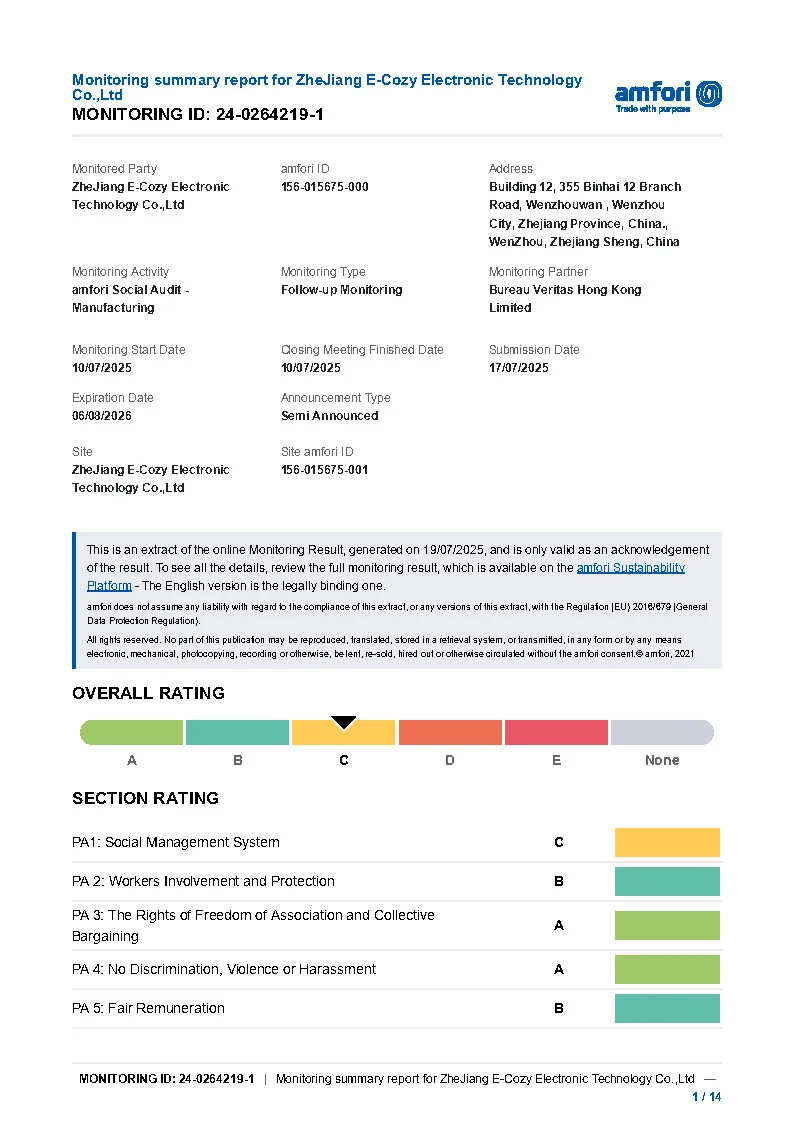

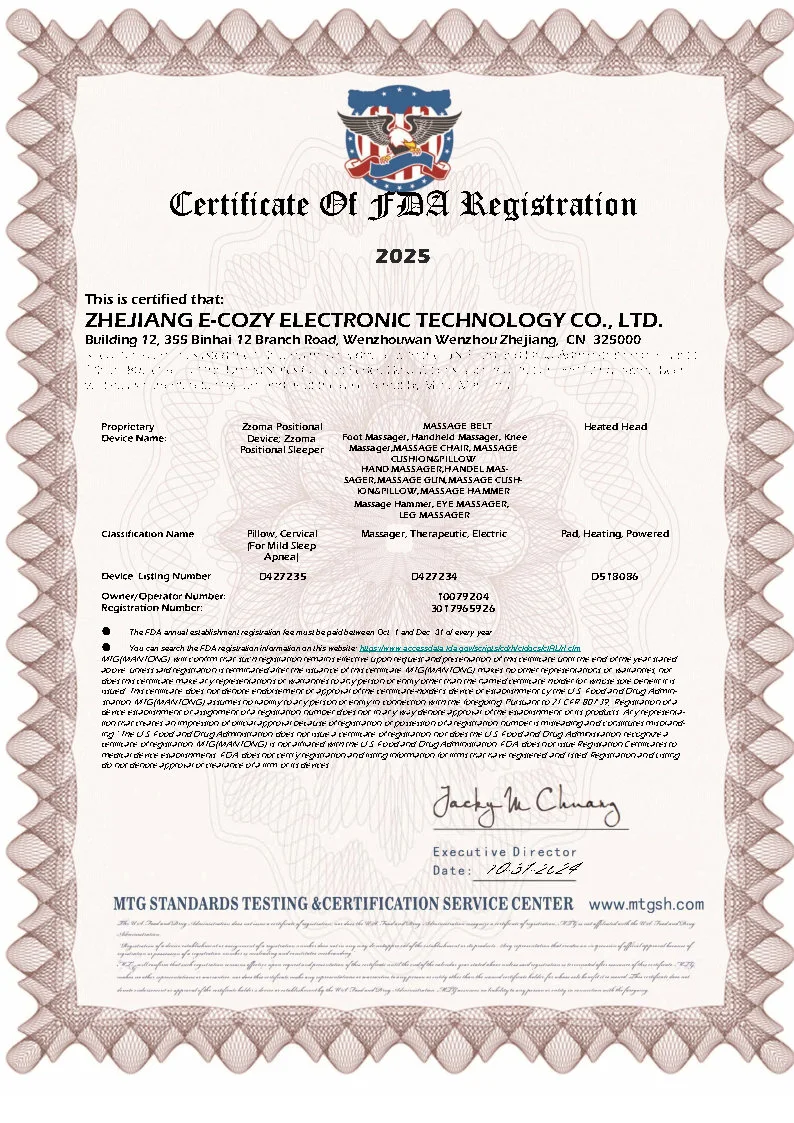

we are committed to delivering high-quality massage and fitness devices that meet the highest industry standards.

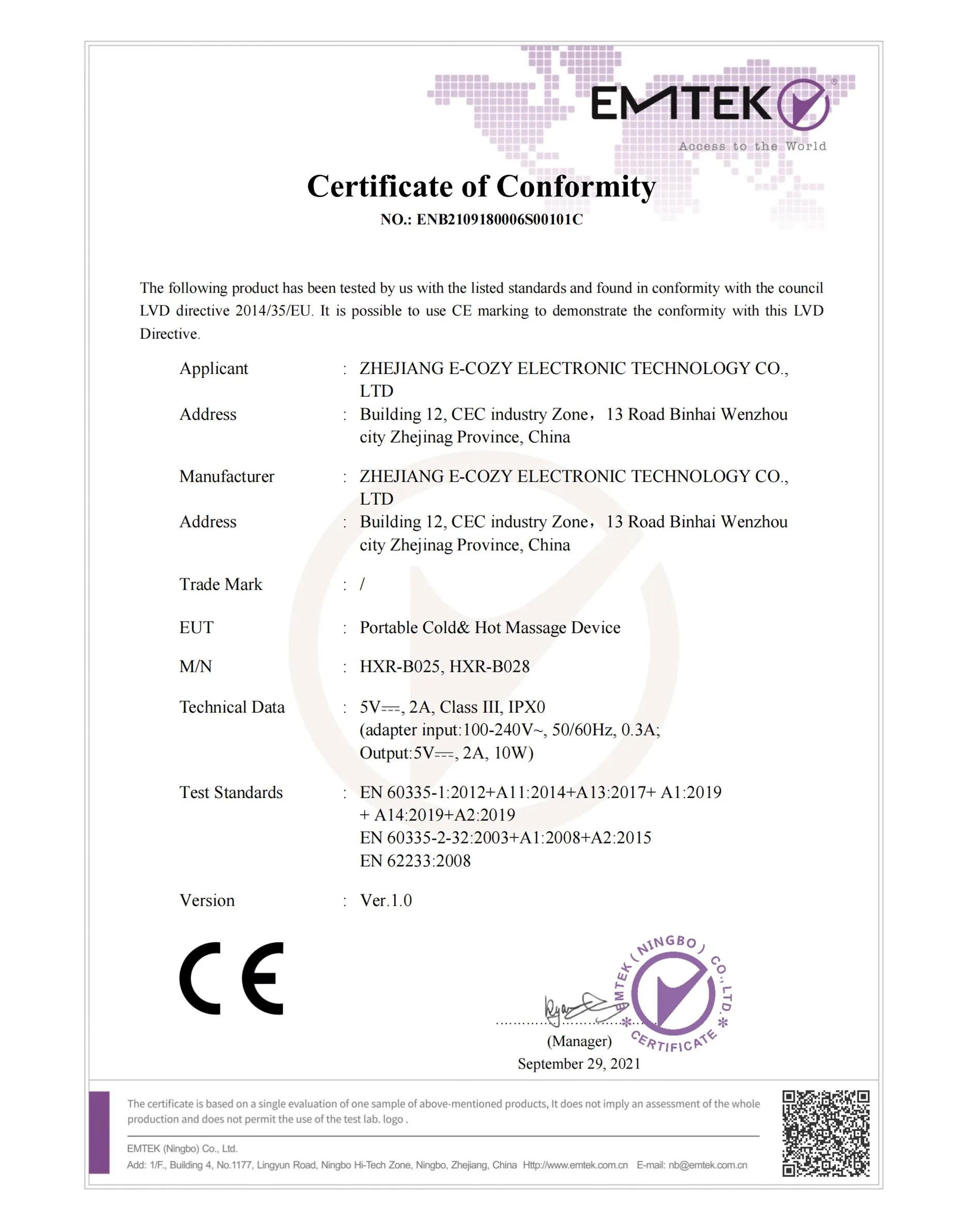

We follow a comprehensive quality control system at every stage of production to ensure the durability, safety, and performance of our products. From raw materials to finished goods, we conduct rigorous testing and inspections to maintain top-notch quality.

Incoming Material Inspection

Before production begins, we conduct thorough incoming material inspections to verify the quality and compliance of every component.

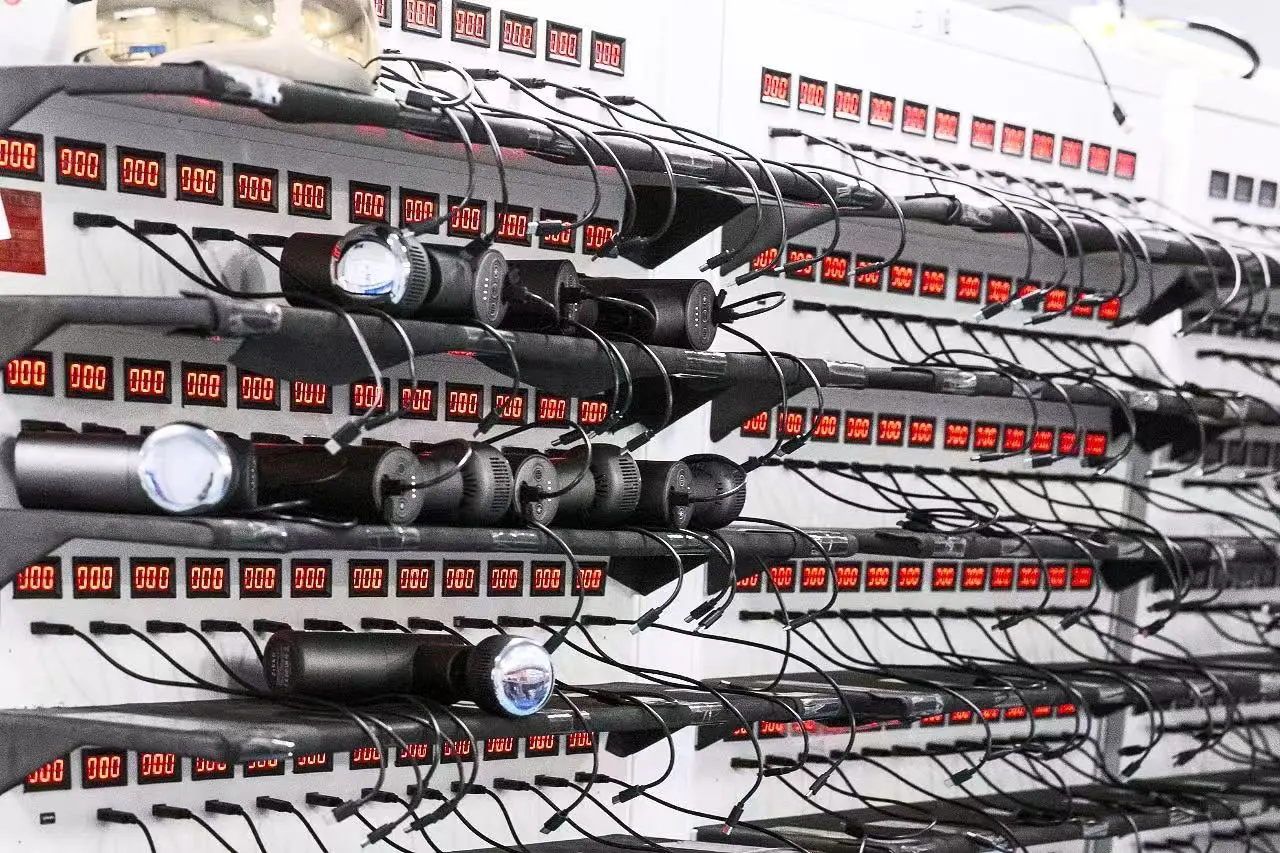

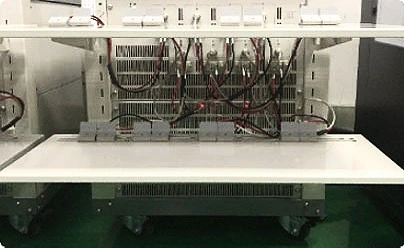

Advanced Product Testing & Reliability

To ensure the highest performance and durability, we conduct a series of product reliability tests in our laboratory.

🛠 Our Testing Standards Include:

✔ High & Low Temperature Resistance – Products are tested under extreme conditions.

✔ Salt Spray & Corrosion Testing – Ensuring longevity in various environments.

✔ Drop & Vibration Testing – Simulating real-world usage scenarios.

✔ Waterproof Testing – Products meet IPX6 standards for water resistance.